Materials, Quality Process

Plywood, For all its strength, plywood is surprisingly so much lighter than solid wood. That makes plywood even more perfect for furniture-making. Heavier solid wood, meanwhile, can prove to be rather unwieldy when crafting furniture or when using it for other commercial applications.

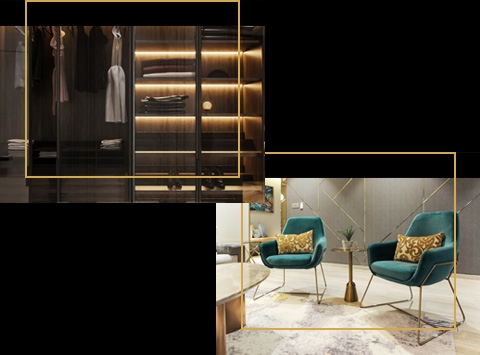

Brass, Brass is soft it can easily be forged and beaten into many shapes. This makes it suitable for intricate designs as are seen on garden furniture, on gates, grill sand railings. Brass is used for making stools, table tops, legs of some items of furniture and for decorative inlay in wooden surfaces.

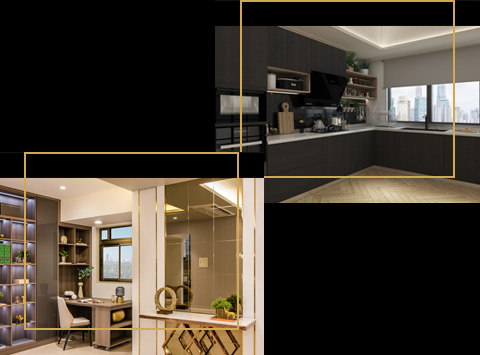

Glass, Glass adds the sophisticated look to the beauty of any furniture. We prefer furniture glass which is not only looks aesthetically superior but also provides a scratch resistant and high durable features. Furniture glass is ideal for table tops, partitions, coffee tables, wardrobe door etc.

Stainless Steel, Stainless steel resists impact, corrosion and it withstands temperatures of up to 500°C. Indeed, owing to these intrinsic characteristics, stainless steel is the material of choice when making professional bespoke furniture.

Quaity Control

1mm Edge Banding

Seamless Hot Pressing

Water & Moisture Proof

Flatness Test

Main tests performed during an inspection of furniture

- Performance check

- Material & color check

- Stability check

- Moisture content

- Accessories check

- Wobbly base test

- Wobbly base test

- Assembly check